Curtis Air Compressors

ECO-Pure Oil Free Rotary Screw

150hp - 340hp

Curtis manufacturers Rotary Screw Compressors from 5HP to 350HP with variable speed options as well as oil-free, single-stage and the most energy-efficient, two-stage technologies. At peak performance, our rotary compressors operate at 100% duty cycle.

Eco-Pure Oil Free Series

110-250 kW(150hp - 340hp) ECO-Pure Variable Speed.

DESCRIPTION

Delivering class zero oil-free air, Curtis “ECO-Pure” revolutionary technology guarantees absolute purity, eliminating contamination risks and setting the bar for industries where pristine air is crucial. From pharmaceuticals to food and beverage, electronics to textiles, FS-Curtis delivers unmatched reliability when it comes to oil-free air.

AIREND

Precision-engineered for maximum reliability, efficiency, and durability, the FS-Curtis two-stage airend delivers unmatched performance in demanding applications.

• Two-Stage Compression Design - Reliable two stage dry screw technology with a track record of performance.

• Advanced Bearing System - Developed with the latest technology for long life and vibration-free operation.

• Integrated Gearbox & Oil Sump - Reduces overall footprint while improving lubrication and heat management.

• High-Performance Sealing System - Maintains peak efficiency during extended operation periods.

• Synchronizing Gears - Provide contact-free power transmission between rotors for smooth, reliable performance.

• Compact & Efficient Design - Integrated water-cooling system (200–250 kW) minimizes footprint and maximizes cooling efficiency.

• ECO-Shield Protection - Special coating on the rotors and housing ensures durability under high temperatures and reduces wear on internal components.

• Corrosion-Resistant Stainless-Steel Rotors - Both stages feature stainless steel rotors, minimizing the risk of seizing and enhancing durability for extended service life

• Jacket Cooling for Both Stages - Maintains consistent temperature control for long-term reliability

COOLING SYSTEM

Engineered for reliability and performance, the FS-Curtis cooling system delivers superior heat management in a compact, easy-to-maintain design.

• Integrated Cooling Block - Combines the intercooler, precooler, aftercooler, and oil cooler into one efficient assembly for simplified service and improved reliability.

• Two-Stage Stainless Steel Cooling - Features stainless steel piping and fins for enhanced durability and corrosion resistance.

• High-Efficiency Aftercooler - Aluminum bar-and plate design ensures excellent thermal transfer and long-term performance.

• Low-Noise, High-Efficiency Fans - Large, low speed radial fans reduce noise while maximizing airflow efficiency.

• Easy Access & Maintenance - Washable panel filters and an open cabinet layout make cleaning and inspection quick and convenient.

• Optimized Air Circulation - Balanced in-cabinet airflow keeps the components running at optimal temperatures for extended life.

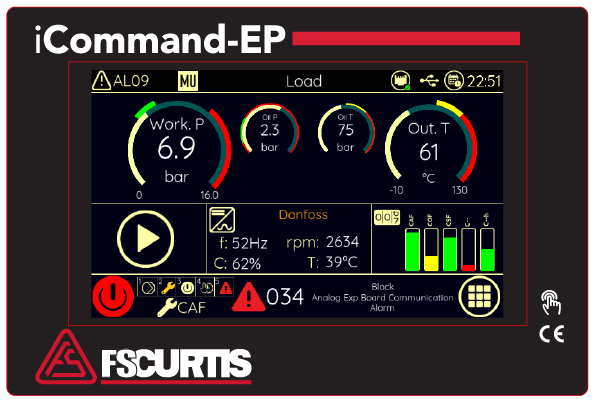

SMART CONTROL, SIMPLIFIED MAINTENANCE

• Intuitive Touchscreen Interface - Easy-to-use display puts full system control at your fingertips.

• Advanced Lead/Lag & Sequencing - Automatically manages up to five compressors, optimizing performance and reducing wear.

• Daily Scheduling Capability - Set precise start/stop times to match your facility’s operating hours and reduce energy waste.

• Centralized Control - All variable speed and compressor operations are coordinated from a single control point for streamlined management.

• ModBus Communication Ready - Seamless integration with your existing building management systems.

• Alarm History Tracking - View the last 20 alarms for quick diagnostics and faster troubleshooting.

• Proactive Maintenance Alerts - Periodic service reminders and maintenance logs help prevent downtime and extend equipment life

Visa & MasterCard Accepted